Stock information

20 minutes minimum delay | June 9, 2023 4:00 PM EST

Operational Strength

Production Capabilities

– DISAMATIC 030 Line: 1 kg to 18 kg

– SINTO FBO IV Line: 10 kg to 50 kg

– Specialized in intricate castings with <0.2 mm mismatch and superior surface finish

Manufacturing Grades

– Grey Iron: EN-GJL 150, 200, 250, 300

– Ductile Iron: EN-GJS 400, 500, 600, 700

– Compacted Graphite Iron (CGI): GJV-300

Machining Infrastructure

– VMC CNC Turning Centers, VTL Turning Centers

– Auto CNC Grinding

– Broaching (up to 16 tons / Ø120 mm)

– Dynamic Balancing and Washing Facilities

Operational Strength

Adjusted EBITDA

$1.92

Adjusted Diluted EPS

Production Capabilities

– DISAMATIC 030 Line: 1 kg to 18 kg

– SINTO FBO IV Line: 10 kg to 50 kg

– Specialized in intricate castings with <0.2 mm mismatch and superior surface finish

– DISAMATIC 030 Line: 1 kg to 18 kg

– SINTO FBO IV Line: 10 kg to 50 kg

– Specialized in intricate castings with <0.2 mm mismatch and superior surface finish

– DISAMATIC 030 Line: 1 kg to 18 kg

– SINTO FBO IV Line: 10 kg to 50 kg

– Specialized in intricate castings with <0.2 mm mismatch and superior surface finish

– Grey Iron: EN-GJL 150, 200, 250, 300

– Ductile Iron: EN-GJS 400, 500, 600, 700

– Compacted Graphite Iron (CGI): GJV-300

– Grey Iron: EN-GJL 150, 200, 250, 300

– Ductile Iron: EN-GJS 400, 500, 600, 700

– Compacted Graphite Iron (CGI): GJV-300

– VMC CNC Turning Centers, VTL Turning Centers

– Auto CNC Grinding

– Broaching (up to 16 tons / Ø120 mm)

– Dynamic Balancing and Washing Facilities

– VMC CNC Turning Centers, VTL Turning Centers

– Auto CNC Grinding

– Broaching (up to 16 tons / Ø120 mm)

– Dynamic Balancing and Washing Facilities

A new era of possibilities ahead Us

With advanced foundry infrastructure, we are poised to produce high-quality castings through a flexible production capacity that meets both small-batch and large-scale demands. Our facilities handle various grades and complex geometries with precision, ensuring reliable delivery and consistent performance across diverse industry segments. The future has never been brighter—as we continue to innovate and grow, we’re ready to meet tomorrow’s challenges with confidence and capability.

A new era of possibilities

With advanced foundry infrastructure, we are poised to produce high-quality castings through a flexible production capacity that meets both small-batch and large-scale demands. Our facilities handle various grades and complex geometries with precision, ensuring reliable delivery and consistent performance across diverse industry segments. The future has never been brighter—as we continue to innovate and grow, we’re ready to meet tomorrow’s challenges with confidence and capability.

LATEST FINANCIAL RESULTS

Q2 2023 Quarterly Results

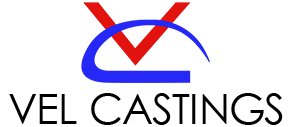

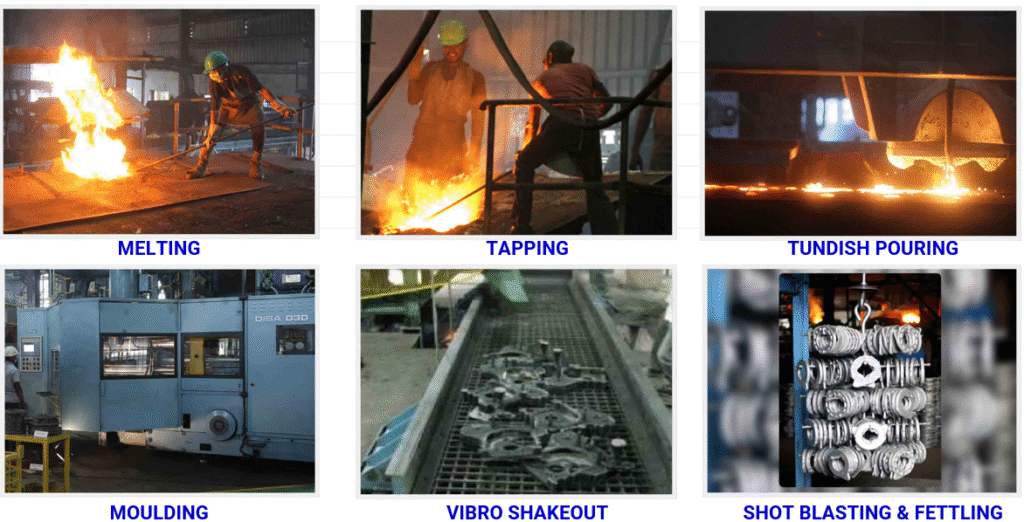

Our Casting Workflow

Plant - I

Plant - II

Plant - |

Melting

Tapping

Tundish Pouring

Moulding

Vibro Shakeout

SHOT BLASTING & FETTLING

Plant - ||

Melting

Tapping

Flexi Pouring

Moulding

Vibro Shakeout